Primary Water

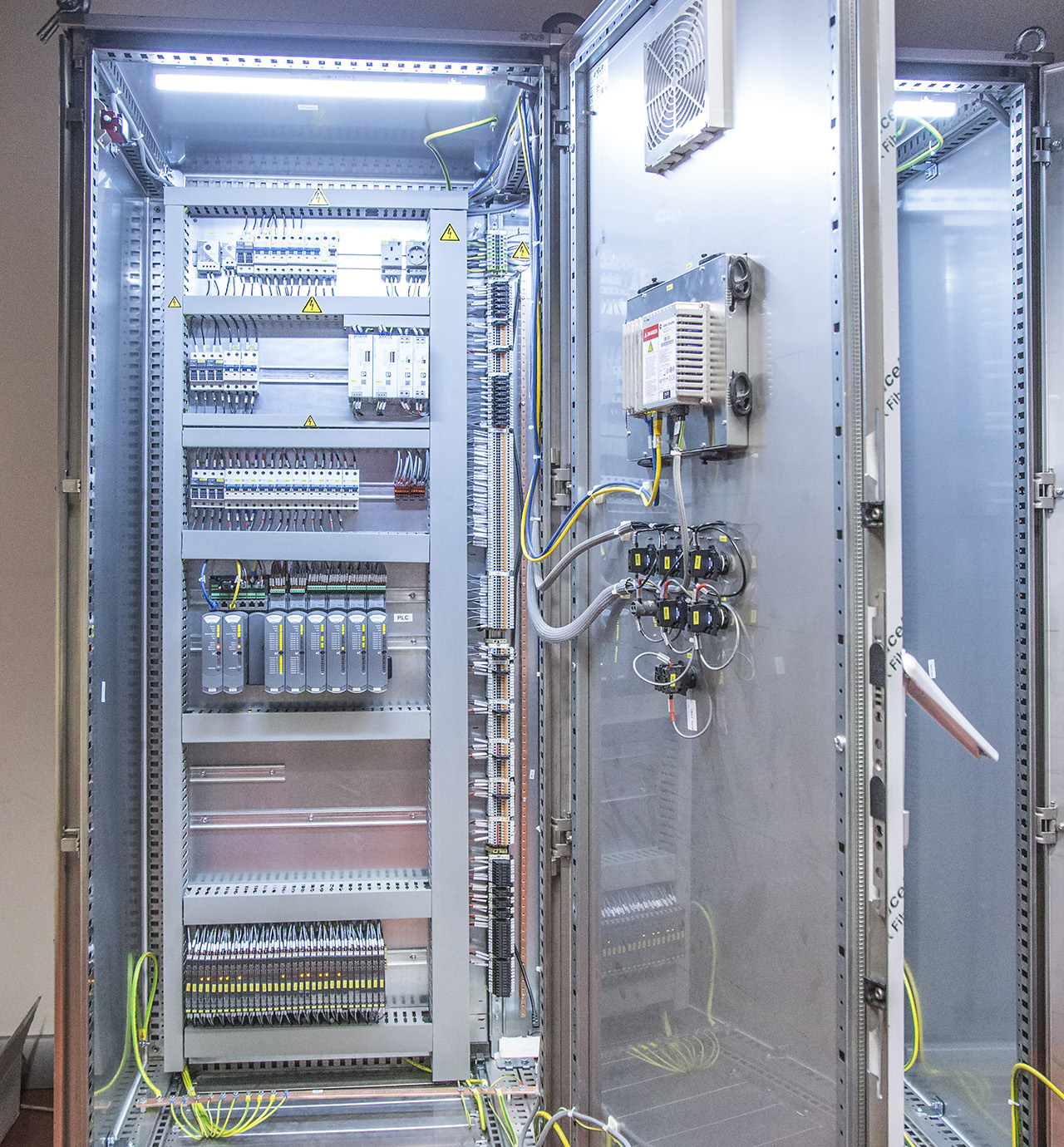

Special Process Packages Designed And Assembled

Advanced Engineering Services

Realizes any tailor-made solution of process control systems for every specific need in many industrial sectors.

Automation

PSC S.p.A. Engineering & Contracting (PSC) Purchasing Department’s mission is to create and maintain excellent relationships with both customers and suppliers.

To assert competitiveness in the global market and uphold our excellent reputation PSC S.p.A. Engineering & Contracting (PSC) has constantly developed its quality control management system over the last 20 and more years.

To assert competitiveness in the global market and uphold our excellent reputation PSC S.p.A. Engineering & Contracting (PSC) has constantly developed its quality control management system over the last 20 and more years.

Special Process Packages Designed And Assembled